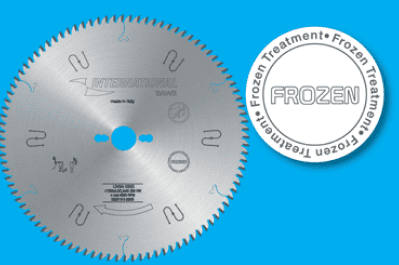

Frozen treatment

Introduction

The Frozen treatment is a HIGH-TECHNOLOGY and HIGH-PERFORMANCE ANT ICORROSI VE coating, which is laid over the blades and is approximately 2-micron thick, including the cutting edge up to the depth of cut being provided for.

High-performance coating

This type of coating protects the body of the blade and prevents it from overheating and then warping while cutting, as these tools are not equipped with rakers. The high non-stick level of this coating allows maximum chip ejection and prevents the resin from building up mainly close to the tips (a disadvantage of all tools that are employed for these kinds of work).

The tool keeps constantly clean and no maintenance intervention is required besides tip sharpening. Thanks to this coating, the tool undergoes reduced stresses while cutting, thus leading to a longer blade lifespan and an increased cutting life.

Therefore, the best employment conditions allow making the most of the potentials of this tool, as the cutting life can be even four times longer than a conventional tool. Also consider that you can employ the tip up to total consumption. The employment of these tools also contributes towards reducing the power absorbed by the motor of the machine.

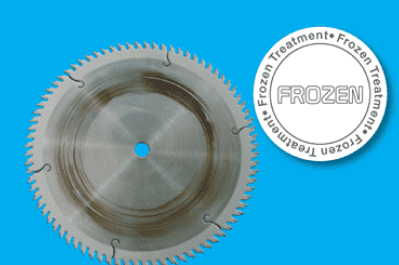

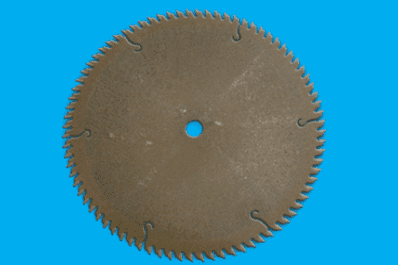

Friction test

Lower temperature of about 1/3 thanks to our treatment, and only slight traces of blackening after prolonged use.

A treated coated sawblade stands out because it lowers temperature by about one third, thus showing on the plate only minor traces of blackening - after a sustained use.

A non coated sawblade posseses lower resistence towards heat, therefore provoking an almost instant overheating effect on certain parts of the sawblades body.

International Saws

Competitors

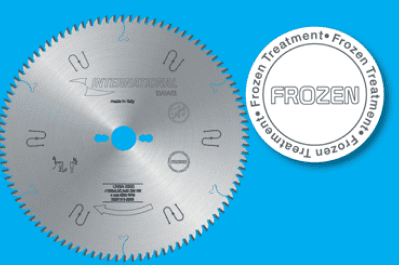

Does not rust

Thanks to the Frozen treatment, International Saws blades do not rust, having a particular resistance to moisture than 5 times higher than the norm.

Due to the special treatment shows a resistance to humidity and therefore to corrosion (rust) about 5 time greater than the standard product..

A non coated sawblade greatly fears humidity. Areas such as the teeth, dampening slots and other grooves and cuts on the sawblades body are at risk.

International Saws

Competitors

Outstanding no-stick

The special Frozen treatment gives the blades to mark International Saws outstanding non-stick properties.

The special “Frozen treatment”, thanks to its non stick features is ideal for cutting resinous woods.

A non-coated sawblade is receptive to the depositing of resins released by certain types of wood.

International Saws

Competitors