Hard metal

Introduction

The carbide used to manufactured a blade’s tips is the most important part of the tool.

The International Saws, aware of this, has been working in the research of the most suitable HW and available on the market to ensure best performance tools on wood derivatives, aluminum, plastic and iron.

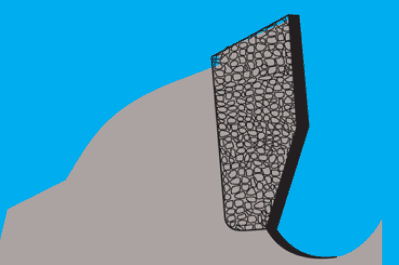

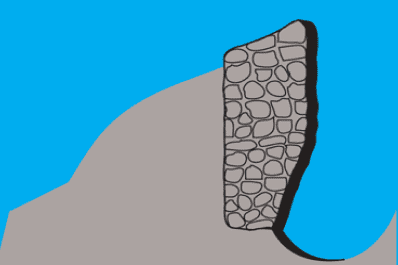

Micro-grain carbide

The use of extremely fine-grained powders (micrograin) has made the carbide more compact and has therefore reduced the possibility of abrasion of the cutting edge, which has improved the cutting quality as well as the life of the blade.

The carbide we use gives the cutting edge the abrasion resistance abrasion resistance, which is essential for good, long-lasting cutting quality. cutting quality.

The competitors blade being all the more exposed to abrasion will have an increasing wearing effect on the cutters therefore leading to a reduction of the duration of the blade itself.

International Saws

Competitors

Maggior durata e resistenzaIncreased durability and resistance

International Saws manufactures its own carbide. By adding titanium to our carbide, we have improved the life of the tips and reduced consequences from chemical attack from resins and glues contained in wood and wood products.

International Saws’s HW alloy metal contains properties of extreme hardness, wearresistance and high temperature stability. It is obtained by mixing Tungsten carbide, Titanium and others metals under powdered form. The mixture is then pressed and sintherized at extreme temperature and pressure.

Other producers of tools acquire their HW from various suppliers, therefore they are not capable of maintaining consant quality, nor changing the HW again with respect to the various wood to be worked.

International Saws

Competitors