Our blades

Introduction

Using the best technology and finest materials, we are able to manufacture sawblades with the following characteristics.

Precision laser cut plates with minimum tolerances.

International Saws’s blades are laser cut in order to maximize the precision of the blade’s body itself.

Sawblade body

International Saws’s blades are laser cut in order to maximize the precision of the blade’s body itself.

Our laser cutting technique allows us to cut very thin sawblades, impossible to obtain with other methods (i.e. die pressing, etc.).

The blade’s expansion slots are also laser cut. Under particularly tough conditions, the centrifugal forces and heat created by friction between the work piece and the blade’s body make other blades dilate and ruin the quality of the cut. International Saws’s specifically engineered expansion slots solve this problem.

The shape and position of the expansion slots are designed to contain noise pollution levels caused by air turbulence created during the rotation of the blade’s.

International Saws

Competitors

Balancing

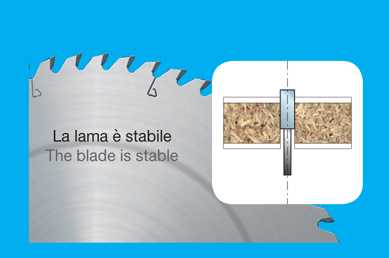

The International Saws blade, unlike lesser quality blades, is individually balanced with fully automated precision equipment to totally eliminate the possibility of harmful vibrations.

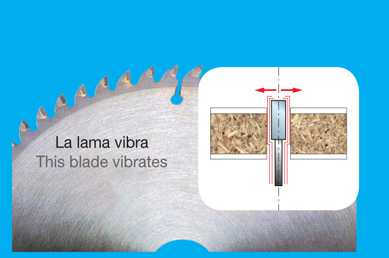

A non balanced blade has different weights in various parts of it’s body. This provokes vibration during rotation.

International Saws

Competitors

Tuning

Tuning parameters are studied based on the blades sizes and types of application

The tuning ring can be seen on most International Saws blades as a faint ring line about 2/3 the diameter of the blade and renders the sawblade more rigid during rotation.

A sawblade without tuning ring is not stable and therefore vibrates producing splintering on the work piece and on the tips.

International Saws

Competitors